Combined Heat and Power Generation for Flexible, Sustainable Energy Generation

Optimize Your Heat and Power Production with MWM Gas Engines

Combined heat and power (CHP) generation with MWM gas engines is a highly energy-efficient technology for the simultaneous generation of heat and power. It uses the waste heat generated during electricity production—which usually remains unused in conventional power plants—to supply heat e.g. for buildings, processes, or district heating networks. The combined generation enables an overall plant efficiency of up to 90 percent, which not only reduces fuel consumption, but also significantly improves the profitability and environmental balance.

Principle of Combined Heat and Power Generation: Dual Use of Energy

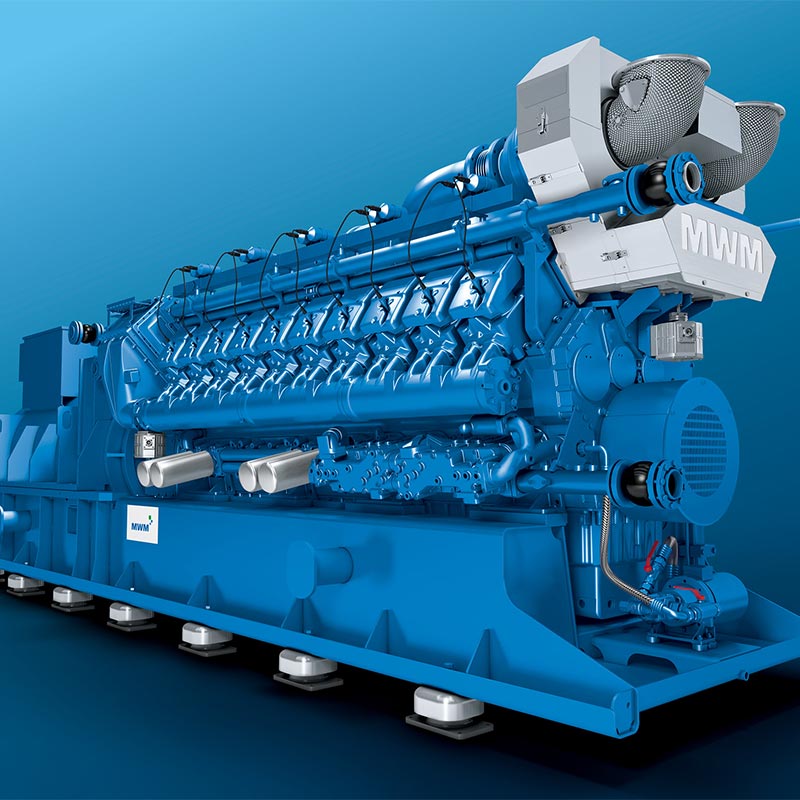

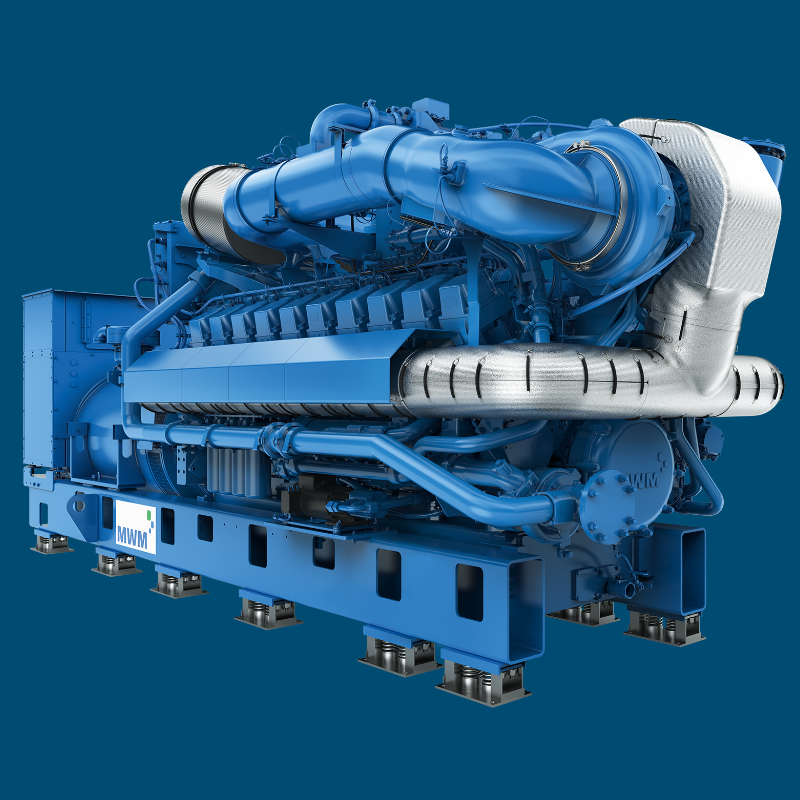

In a cogeneration power plant, a powerful MWM gas engine drives a generator that produces electricity. At the same time, the engine cooling protects the engine by extracting the heat, while the heat exchanger extracts the heat from the exhaust gas and makes use of its energy. Combined generation thus ensures maximum utilization of the fuel used and significantly reduced carbon emissions compared to separate generation of heat and power.

Use of Steam Generators

The high thermal energy of the exhaust gas heat can be used to produce steam from water using steam generators. This steam can be utilized in various ways, e.g. in industrial processes, to heat buildings, or in district heating networks. In larger plants, the steam can even drive a steam turbine to generate more electricity. MWM offers not only efficient gas engines, but also CHP plants with steam generators tailored to the respective application.

Absorption Chiller (Trigeneration/CCHP)

CCHP (combined cooling, heat and power) generation, also known as trigeneration, is a highly efficient way to generate heat, power, and cold at the same time. In addition to the functions of a conventional CHP plant, an absorption chiller converts the exhaust gas heat into cold, which can be used to cool buildings such as hospitals, hotels, or shopping centers, for production processes, or for food storage.

FAQ

How does combined heat and power (CHP) generation with MWM gas engines work?

CHP technology concurrently generates heat and power in a cogeneration power plant. An MWM gas engine drives a generator that produces electricity, while the resulting waste heat is used for heating purposes. Thus, the fuel is used twice as efficiently, increasing the overall efficiency to up to 90 percent.

What kind of applications are MWM CHP plants suitable for?

MWM CHP plants are scalable and suitable for deployment in many areas, from residential areas, municipal utilities, and industrial plants to hospitals and biogas plants. They increase the energy efficiency and security of supply and are suitable for grid-parallel operation, peak load coverage, or as an emergency power solution.

What types of gas can be used in MWM gas engines?

MWM gas engines are versatile and run on various types of gas, such as natural gas, biogas, landfill gas, sewage gas, and mine gas. Moreover, it is already possible to operate these engines with natural gas with a hydrogen admixture of up to 25 vol%. Thus, they are ready for future energy supply requirements.

Be on the Safe Side with Combined Heat and Power Generation and MWM Gas Engines

High Energy Efficiency and Security of Supply

- High energy efficiency: Maximum utilization of the utilized fuel through combined heat and power generation

- Combined heat and power (CHP) generation: Simultaneous generation of power and usable heat in a single plant

- Improved primary energy utilization: Significantly lower primary energy consumption compared to separate heat and power generation

- High overall efficiency: Efficiencies of up to 90%—much higher than the levels achieved by conventional power plants

- Reliable supply: High operational reliability and constant energy availability, even under fluctuating grid conditions

Reduced Operating Costs

- Significant reduction in energy costs: On-site generation of electricity with a cogeneration power plant significantly reduces ongoing energy costs.

- Independence from external power providers: Producing your own energy makes you independent of electricity price increases and supply fluctuations on the energy market.

- Short payback period: The high efficiency and economical use of fuels ensure short investment amortization periods.

- Long-term planning security: Stable operating costs and calculable energy prices deliver economic security in the long term.

- Optimized use of existing resources: The simultaneous use of heat and power increases the overall efficiency of the company’s energy supply.

Maximum Flexibility

- Flexible output adjustment: The output of MWM gas engines and CHP plants can be adjusted quickly and precisely to changing energy needs.

- High operational reliability: Durable components and sturdy technology ensure reliable, trouble-free power supply.

- Use in the event of seasonal fluctuations: Particularly suitable for companies with seasonally varying energy consumption, from winter to summer operation

- Scalable operating modes: From partial load to full load—flexible adaptation to operational and grid requirements

- Minimize downtimes: Modular design and easy maintenance maximize plant availability.

- Support for peak load management: Flexible operation enables efficient coverage of peak loads and contributes to grid stability.

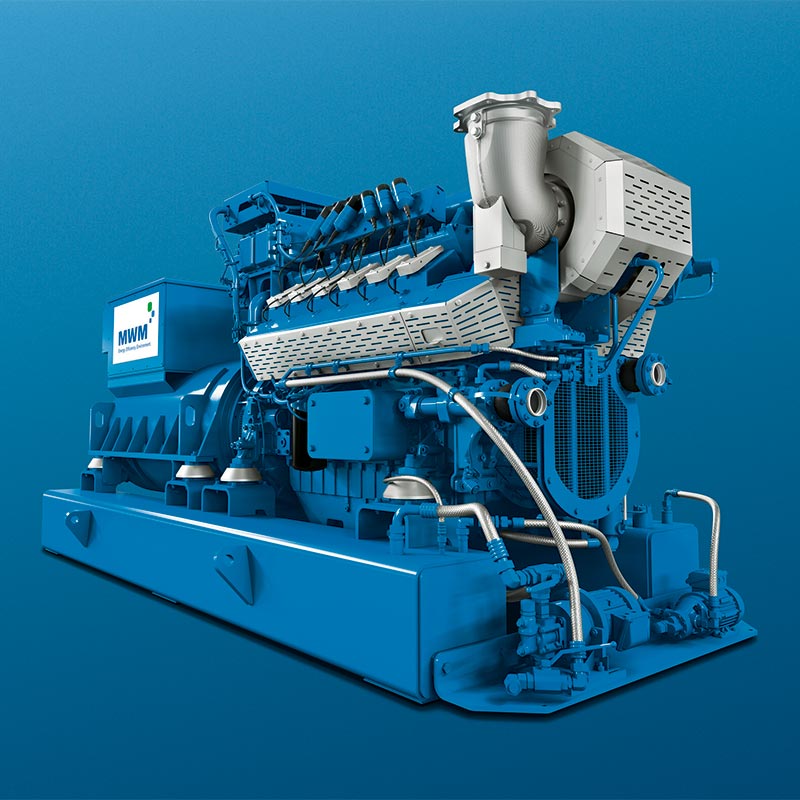

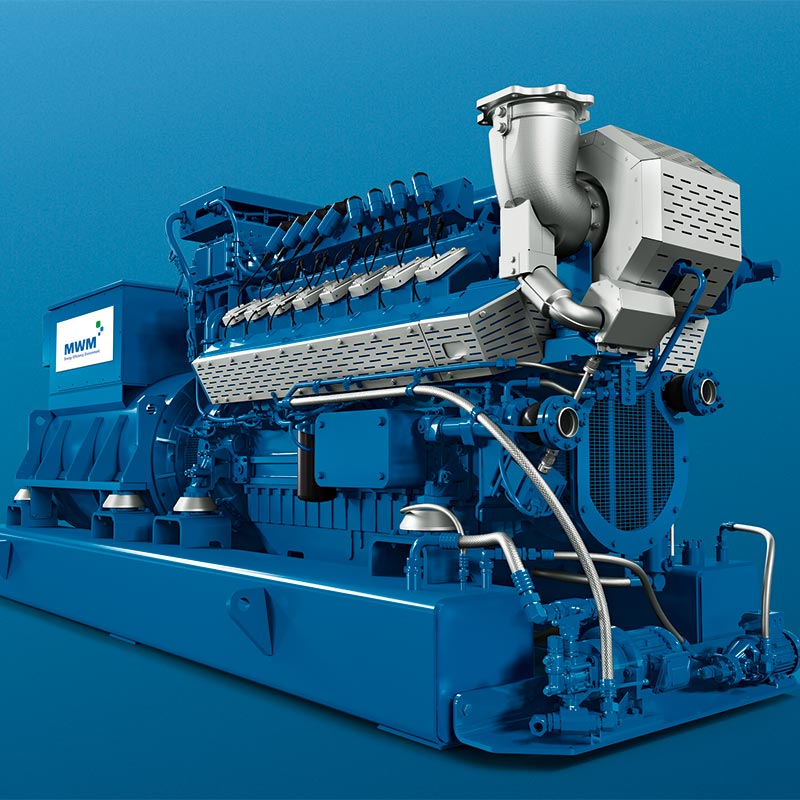

MWM Gas Engines for Combined Heat and Power (CHP) Generation

MWM Combined Heat and Power (CHP) Plants in Central Asia and Eastern Europe

Here you can find our successfully implemented power plant projects.

Your Experts and Contacts for Combined Heat and Power Plants

Any questions regarding the implementation of your combined heat and power plant? Our MWM sales and service contacts will be happy to help you.