MWM Container Cogeneration Power Plants

The Compact Solution for Distributed Energy Projects

Efficient, Mobile, Fully Integrated

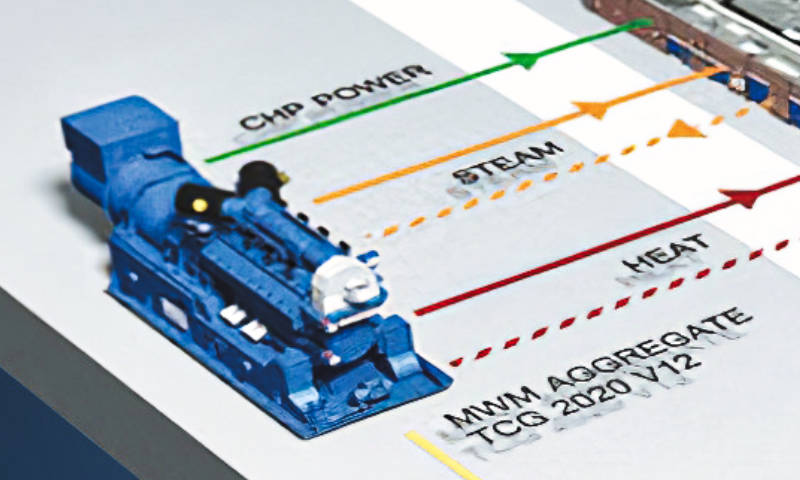

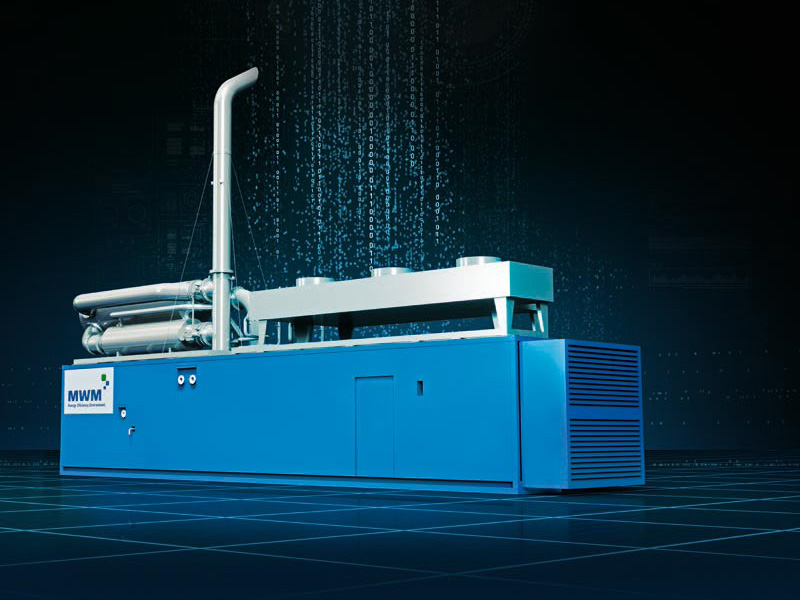

MWM container cogeneration power plants represent a smart solution for distributed energy generation. The ready-to-connect units are based on gas engines from the TCG 3016, TCG 3020, and TCG 2020 series. All relevant components, such as the engine, the generator, and the cooling system, are integrated in a compact system. This reduces the planning overhead, facilitates the commissioning, and establishes a reliable basis for projects in the industry, utility providers, and commerce.

Modular Technology for Maximum Flexibility

The container cogeneration power plants are characterized by high flexibility and easy handling. They can be deployed at different locations, are quick to install, and can easily be moved or expanded if necessary. This makes them equally suitable for stationary applications and for temporary or mobile use. The small footprint facilitates the efficient use of the available space, even where space is limited.

Smart Concept for Continuous Operation

The smart container concept simplifies day-to-day operation and ensures high plant availability. The sturdy steel construction with integrated sound and heat insulation reliably protects the technology. At the same time, the modules are designed so as to facilitate and speed up the maintenance and service.

MWM Container CHP Plant—Benefits at a Glance

Flexible Energy Supply

- Versatile solution for various applications and industries/li>

- Ideal for use in distributed energy supply systems

- Compact design with highly efficient heat and power generation

- Flexible deployment directly at the place of use

Custom-Tailored, Needs-Oriented Configuration

- Preassembled modules directly from the manufacturer

- Tailored to site conditions and output requirements

- Easy transport, fast installation

- Scalable depending on the plant’s energy demand

High Availability, Low Installation Costs

- Reduced operating costs thanks to maintenance-friendly container design

- High internal pressure reduces dust load in the system

- Roof structure available pre-assembled or in the form of modules

- Durable design for long-term continuous operation

Responsive, Powerful Island-Mode Operation

Why the TCG 2032B Container Is Especially Suitable for Off-Grid Applications

- Container contains all necessary components und is a ready-to-deploy-and-use solution for independent power supply.

- The modular container concept features a compact design and a high output of 4.5 MW.

- Fast installation and suitable for mobile deployment in remote or temporary locations.

- Especially suitable for operation without connection to the public power grid, ensures reliable power supply

- Significantly lower investment costs compared to conventional solutions thanks to standardized container layout

- Flexible customization options for different application areas and industries

- Stable, reliable power supply even under high loads, as the plant was developed for constant performance under demanding operating conditions

Overview: Possible Applications for MWM Container Cogeneration Power Plants

FAQ

What are the advantages of MWM container cogeneration power plants over stationary plants?

The pre-assembled container solutions from MWM are compact systems that can be transported easily and be installed within a very short time. Thanks to their small footprint, they represent a flexible option for locations with limited space or temporary energy requirements. This makes them especially suitable for projects that endeavor to deliver mobility and rapid availability.

Which application areas are MWM cogeneration power plants suitable for?

Container cogeneration power plants are highly versatile. For example, they can be used for energy supply in industrial plants, for district heating networks at the municipal level, in agricultural operations, or in biogas plants. They also constitute an economical solution for IPP projects and in commercial properties that require reliable heat and power generation directly on site.

How do MWM container cogeneration power plants contribute to the reduction of operating costs?

Long maintenance intervals and high efficiency significantly reduce operating costs. The optimized engine technology ensures low lubricating oil consumption, which also contributes to the profitability of the plant as a whole. This aspect is especially beneficial for continuous operation.

What is the electrical output range of MWM container cogeneration power plants?

Depending on the requirements and the gas engine used, the plants offer an electrical output from 400 to 2,300 kW, covering a broad spectrum from small distributed projects to large energy units.

Which fuels are suitable for the operation?

MWM container cogeneration power plants can be flexibly operated with different types of gas, including natural gas, biogas, landfill gas, sewage gas, and natural gas with a hydrogen admixture of up to 25 vol%. This versatility enables individual adaptation to local conditions.

To what extent can MWM container cogeneration power plants be customized?

The plants are preconfigured at the factory and fine-tuned to the needs at the destination. Their modular structure and scalability enable them to be expanded depending on the energy demand. Thanks to their smart design, they can quickly be set up and dismantled. This is especially advantageous when switching to another project or for temporary use.

Insights: Application of the MWM Container Cogeneration Power Plant

The international MWM website features selected projects in which container cogeneration power plants are in use worldwide.

Your Sales and Service Inquiries

Competence for Your Energy Future

MWM provides you with expert advice and reliable service for your planning, purchase, or maintenance. Our dedicated team will assist you with their expertise and full commitment to ensure that your projects run smoothly. Benefit from custom-tailored solutions for a reliable pathway to your goal.

Your Personal MWM Contact

Make an Appointment with Your Personal MWM Contact

Protect Your Investment

For a Strong Future for Your Engines

Genuine MWM spare parts suit your plant perfectly, guaranteeing performance, efficiency, and a long useful life. Always get the best quality for your energy supply.