MWM TCG 2032/2032B Gas Engine

Reliable Energy Solutions for IPP Plants

Versatile and Powerful

The TCG 2032 gas engines represent a flexible solution for a wide range of energy projects. With an electrical output range from 3,000 to 4,500 kW, these engines are suitable for numerous applications, e.g. for municipal energy suppliers, large production and industrial operations, mining and raw materials extraction, and greenhouses. Thanks to its sturdy design and high operational reliability, the TCG 2032 series is especially suitable for continuous heat and power generation under demanding conditions. Being compatible with a wide range of fuels, including natural gas, APG, propane gas, mine gas, coke oven gas, sewage gas, landfill gas, biogas, as well as natural gas with hydrogen admixtures of up to 25 vol%, the series is highly flexible.

Reliable Performance for High Energy Demand

The TCG 2032 series shows its strengths particularly in projects of independent energy suppliers with permanently high energy requirements. Plants with a total power requirement of up to 100 MW benefit from the reliable continuous output of this series. Thanks to its high efficiency, low operating costs, and longer maintenance intervals, the engine is the ideal choice for operators who rely on long-term availability and economical operation. The gas engines support both power-only generation and combined operation with heat extraction.

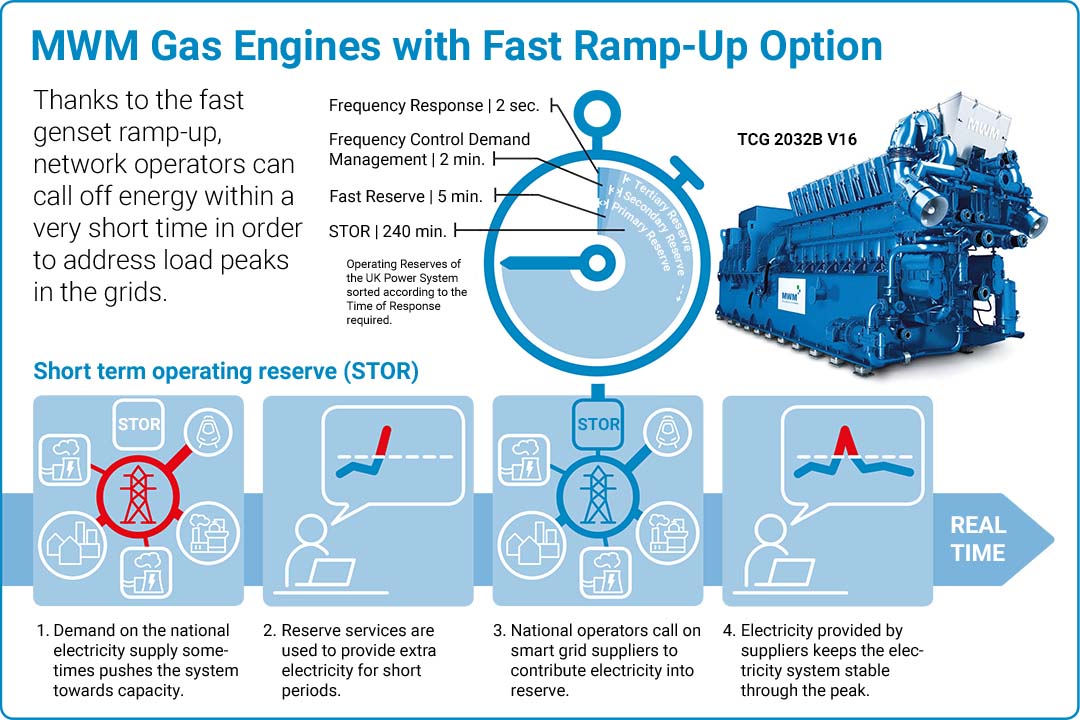

Fast Ramp-up, Easy Integration

The TCG 2032B V16 version with fast ramp-up option enables the plant to be started very fast. This is key benefit for applications in the refinery or petrochemical industry, where fast reaction times are required. The TCG 2032 and 2032B thus combine high performance with practical implementation and high reliability during operation.

MWM TCG 2032 Gas Engine—Benefits at a Glance

Flexible Deployment Options

- Ideally suited for energy projects with high output requirements in combined heat and power generation

- Suitable for various areas such as industrial plants, municipal utility providers, and critical infrastructure

- Supports independent power producers (IPP) projects

- Output range from 3,000 to 4,500 kW for a wide range of requirements

Adaptability

- Flexible use for changing output requirements in different industries

- TCG 2032B V16 also available with fast ramp-up option

- Suitable for operation with various types of gas, including natural gas, APG, propane gas, mine gas, coke oven gas, sewage gas, landfill gas, and biogas

- Supports operation with natural gas with hydrogen admixture of up to 25 vol%

High Availability and Operational Reliability

- Outstanding reliability in continuous operation with low maintenance costs

- Long maintenance intervals reduce downtimes and lower operating costs

- Optimized turbocharger technology increases engine availability and efficiency

- Ideal for projects with long runtimes and continuous energy requirements

Responsive, Powerful Grid Operation

What Makes the TCG 2032B V16 with Fast Ramp-Up Option so Special

- Ideal for fluctuating feed-in, e.g. from wind and solar power plants, to buffer supply bottlenecks

- Enables flexible switching between standard and fast ramp-up depending on grid requirements

- In fast ramp-up mode, engine reaches full performance in grid operation within five minutes of the start command

- Supports grid operators in stabilizing the power supply at peak times

- Suitable for deployment in short-term grid reserve programs such as the Short-Term Operating Reserve (STOR)

Overview: Deployment Options of the TCG 2032/2032B

FAQ

What are the benefits of the TCG 2032 series for industrial applications?

Thanks to their sturdy design and high power density, TCG 2032 series gas engines are ideally suited for continuous operation in industrial plants. Especially in large IPP projects with high energy demands, reliable and efficient power generation ensures maximum operational reliability.

What maintenance benefits does the TCG 2032 series offer?

The TCG 2032 and TCG 2032B models are characterized by long maintenance intervals and an integrated lubricating oil system. This greatly reduces both maintenance times and operating costs. At the same time, the plant availability increases, which is particularly advantageous for continuously operated power plants.

What are the cost benefits for plant operators?

The low lubricating oil consumption, extended maintenance intervals, and high efficiency of the TCG 2032 and 2032B reduce operating costs. This results in a shorter payback period. For operators, this means an economical solution with predictable profitability.

What are the benefits of the fast ramp-up option of the TCG 2032B?

The fast ramp-up option, which is available for the V16 variant, enables the plant to be started more speedily. Full performance can be reached within a very short time. This is often very important, especially for short-term energy requirements, e.g. in the grid reserve.

Technical Information on the TCG 2032/2032B for Download

MWM TCG 2032 and 2032B Gas Engine

The brochure provides a compact overview of the gas engines of the TCG 2032 series. It features technical data and possible application scenarios and explains how the engines use combined heat and power generation to utilize energy sources very efficiently and regardless of the type of gas used.

NOTICE: Click this brochure to access the digital publishing platform issuu.com. This website is governed by the issuu Privacy Policy.

All languages on issuu:

Download PDF:

MWM 25H2-Kit for TCG 2032 and TCG 2032B

This information sheet lists all components and system parts included in the 25H2-Kit for operation with a hydrogen admixture of up to 25 vol%. The overview facilitates planning and technical integration into existing plants.

NOTICE: Click this brochure to access the digital publishing platform issuu.com. This website is governed by the issuu Privacy Policy.

All languages on issuu:

Download PDF:

Insights: Application of the TCG 2032 and 2032B

Visit the international MWM website to learn more about projects in which the TCG 2032 and 2032B gas engines are successfully used.

Your Sales and Service Inquiries

Competence for Your Energy Future

MWM provides you with expert advice and reliable service for your planning, purchase, or maintenance. Our dedicated team will assist you with their expertise and full commitment to ensure that your projects run smoothly. Benefit from custom-tailored solutions for a reliable pathway to your goal.

Your Personal MWM Contact

Make an Appointment with Your Personal MWM Contact

Performance Data: TCG 2032 / TCG 2032B Gas Engine

Natural Gas Applications, NOx ≤ 500 mg/Nm3 *

| TCG 2032 V12 R = Optimized for high total efficiency |

|||

|---|---|---|---|

| Engine type | 50 Hz | 60 Hz** | |

| Electrical output | kW | 3,333 | 3,000 |

| Mean effective pressure | bar | 20.0 | 20.1 |

| Thermal output ± 8% | kW | 3,238 | 2,877 |

| Electrical efficiency | % | 43.9 | 43.9 |

| Thermal efficiency | % | 42.6 | 42.1 |

| Total efficiency | % | 86.5 | 85.9 |

| Power to heat ratio*** | 1.03 | 1.04 | |

| TCG 2032 V16 R = Optimized for high total efficiency |

|||

|---|---|---|---|

| Engine type | 50 Hz | 60 Hz** | |

| Electrical output | kW | 4,300 | 4,000 |

| Mean effective pressure | bar | 19.4 | 20.2 |

| Thermal output ± 8% | kW | 4,164 | 3,866 |

| Electrical efficiency | % | 44.1 | 43.8 |

| Thermal efficiency | % | 42.7 | 42.4 |

| Total efficiency | % | 86.8 | 86.2 |

| Power to heat ratio*** | 1.03 | 1.03 | |

| TCG 2032B V16 R = Optimized for high total efficiency |

|||

|---|---|---|---|

| Engine type | 50 Hz | 60 Hz** | |

| Electrical output | kW | 4,500 | 4,050 |

| Mean effective pressure | bar | 20.3 | 20.4 |

| Thermal output ± 8% | kW | 4,361 | 3,891 |

| Electrical efficiency | % | 44.6 | 44.3 |

| Thermal efficiency | % | 43.2 | 42.6 |

| Total efficiency | % | 87.8 | 86.9 |

| Power to heat ratio*** | 1.03 | 1.04 | |

* 5% O2 and dry exhaust gases

** On request

*** The power to heat ratio is calculated by dividing the electrical efficiency by the thermal efficiency. Please remember that this is a theoretical value that may deviate from actually measured values.

The data in this chart are for information only and are not binding. The information given in the offer is authoritative. Further generator set variants are available with different generators.

Natural Gas Applications with 25 vol% Hydrogen (NOx ≤ 500 mg/Nm3* / 1.0 g/bhph*)

| TCG 2032 V12 R+ High Response plus 25H2-Kit = Optimized for high total efficiency with 25 vol.% hydrogen kit |

|||

|---|---|---|---|

| Engine type | 50 Hz | 60 Hz | |

| Electrical output*** | kW | 3,333 | 3,000 |

| Electrical efficiency | % | 43.7 | 43.7 |

| Thermal efficiency** (±8 %) | % | 42.7 | 42.1 |

| Total efficiency | % | 86.4 | 85.8 |

| Power to heat ratio**** | 1.02 | 1.03 | |

| TCG 2032 V16 R+ High Response plus 25H2-Kit = Optimized for high total efficiency with 25 vol.% hydrogen kit |

|||

|---|---|---|---|

| Engine type | 50 Hz | 60 Hz | |

| Electrical output*** | kW | 4,300 | 4,000 |

| Electrical efficiency | % | 44.0 | 43.8 |

| Thermal efficiency** (±8 %) | % | 42.8 | 42.5 |

| Total efficiency | % | 86.8 | 86.3 |

| Power to heat ratio**** | 1.03 | 1.03 | |

| TCG 2032B V16 R+ High Response plus 25H2-Kit = Optimized for high total efficiency with 25 vol.% hydrogen kit |

|||

|---|---|---|---|

| Engine type | 50 Hz | 60 Hz | |

| Electrical output*** | kW | 4,500 | 4,050 |

| Electrical efficiency | % | 44.5 | 44.3 |

| Thermal efficiency** (±8 %) | % | 43.3 | 42.7 |

| Total efficiency | % | 87.8 | 87.0 |

| Power to heat ratio**** | 1.03 | 1.04 | |

* 5% O2 and dry exhaust gases

** Exhaust gas cooled to 120 °C for natural gas

*** According to ISO 3046-1

**** The power to heat ratio is calculated by dividing the electrical efficiency by the thermal efficiency. Please remember that this is a theoretical value that may deviate from actually measured values.

The data in this chart are for information only and are not binding. The information given in the offer is authoritative. Further generator set variants are available with different generators.

Biogas, Landfill Gas, and Sewage Gas Applications, NOx ≤ 500 mg/Nm3 *

| TCG 2032 V16 X = Optimized for operation with biogases |

|||

|---|---|---|---|

| Engine type | 50 Hz | 60 Hz** | |

| Electrical output | kW | 3,770 | 3,510 |

| Mean effective pressure | bar | 17.0 | 17.0 |

| Thermal output ± 8% | kW | 3,487 | 3,117 |

| Electrical efficiency | % | 42.9 | 43.3 |

| Thermal efficiency | % | 39.7 | 38.5 |

| Total efficiency | % | 82.7 | 81.8 |

| Power to heat ratio*** | 1.08 | 1.12 | |

* 5% O2 and dry exhaust gases

** On request

*** The power to heat ratio is calculated by dividing the electrical efficiency by the thermal efficiency. Please remember that this is a theoretical value that may deviate from actually measured values.

The data in this chart are for information only and are not binding. The information given in the offer is authoritative. Further generator set variants are available with different generators.

Protect Your Investment

For a Strong Future for Your Engines

Genuine MWM spare parts suit your plant perfectly, guaranteeing performance, efficiency, and a long useful life. Always get the best quality for your energy supply.

Specifications and Service Intervals: TCG 2032 / TCG 2032B Gas Engine

Dimensions and Weights

| TCG 2032 V12 | |||

|---|---|---|---|

| Engine type | 50 Hz | 60 Hz* | |

| Length | mm | 7,860 | 8,000 |

| Width | mm | 2,660 | 2,790 |

| Height | mm | 3,390 | 3,390 |

| Dry weight genset | kg | 43,100 | 49,780 |

| Bore / stroke | mm | 260/320 | 260/320 |

| TCG 2032 V16 | |||

|---|---|---|---|

| Engine type | 50 Hz | 60 Hz* | |

| Length | mm | 9,271 | 9,420 |

| Width | mm | 2,790 | 2,790 |

| Height | mm | 3,390 | 3,390 |

| Dry weight genset | kg | 51,200 | 52,400 |

| Bore / stroke | mm | 260/320 | 260/320 |

* On request

The data in this chart are for information only and are not binding. The information given in the offer is authoritative. Further generator set variants are available with different generators.

Service Intervals

| First service (check valve clearance)* | Mixture cooler cleaning | |

|---|---|---|

| Natural gas | 4,000 oh | 20,000 oh |

| Cylinder head inspection | Major overhaul | |

|---|---|---|

| Natural gas | 40,000 oh | 80,000 oh |

* “after commissioning (E10)”

The data in this chart are for information only and are not binding. The information given in the offer is authoritative. Further generator set variants are available with different generators.