MWM Gas Engines, Container CHP Plants, and Genuine Spare Parts

For the Successful Rollout of Your Distributed Energy Project

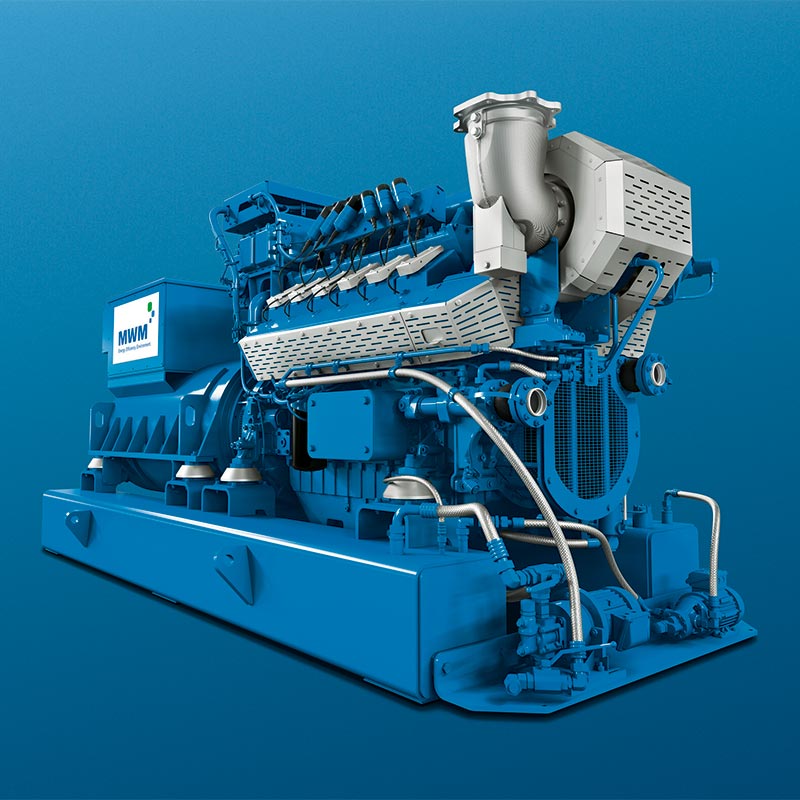

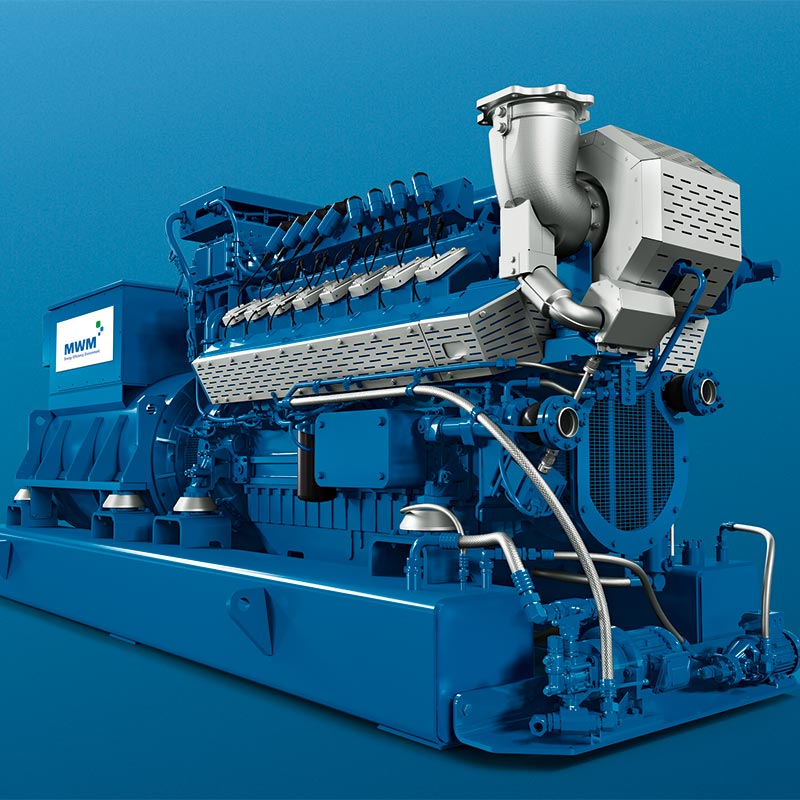

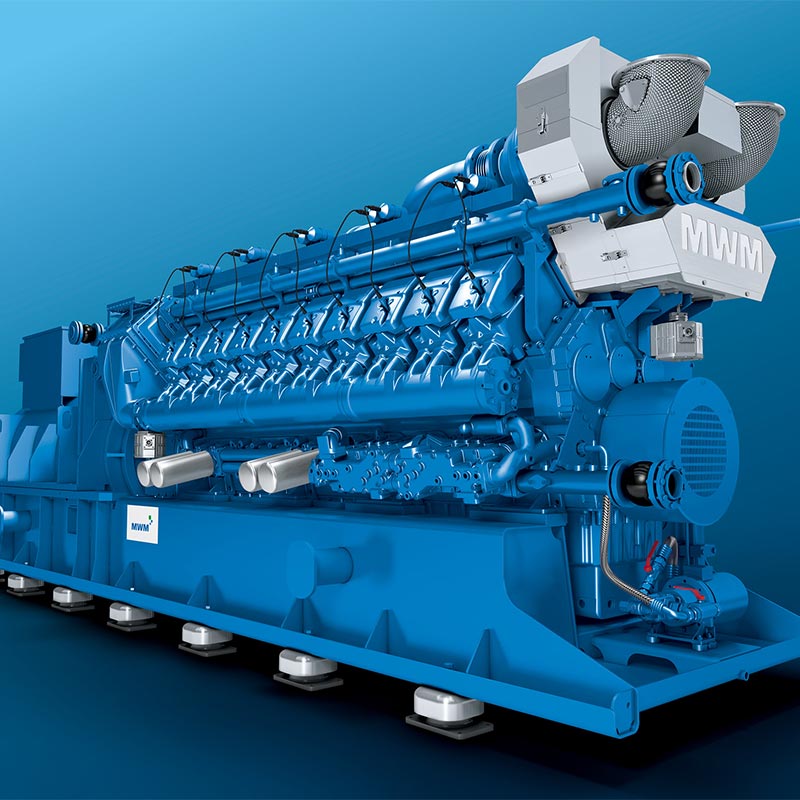

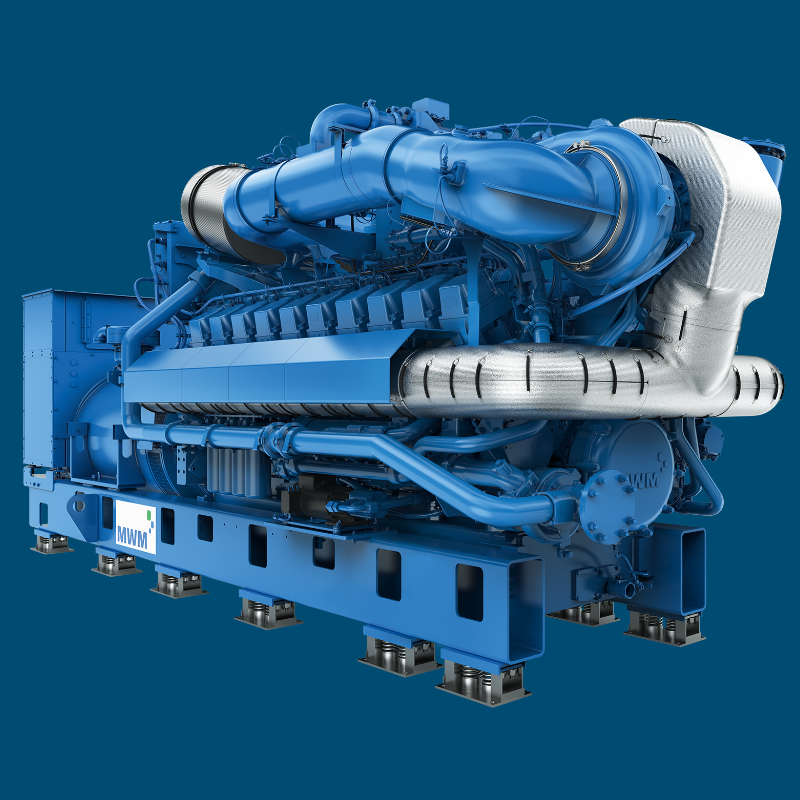

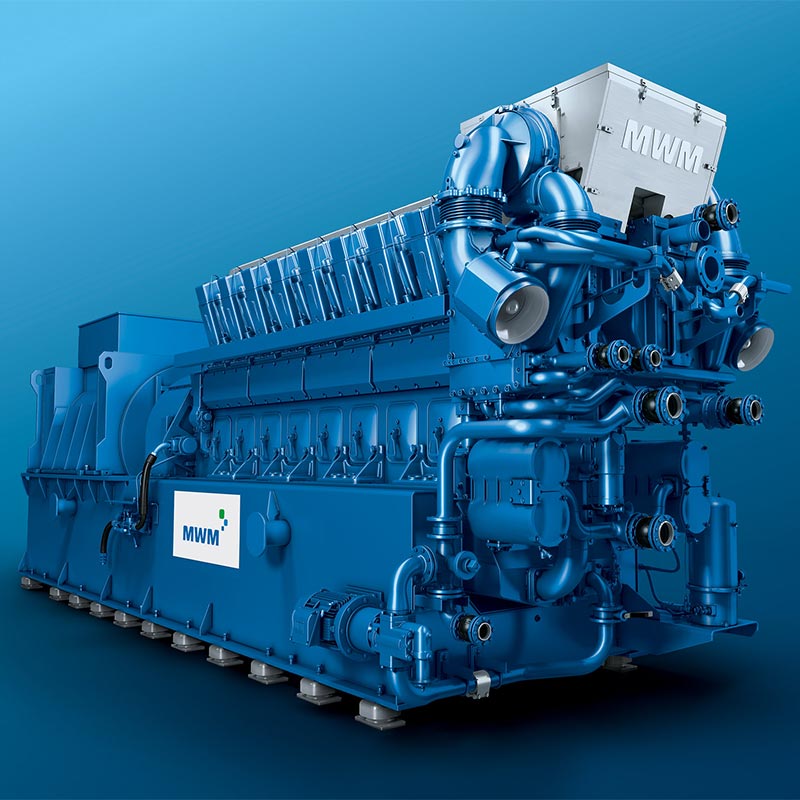

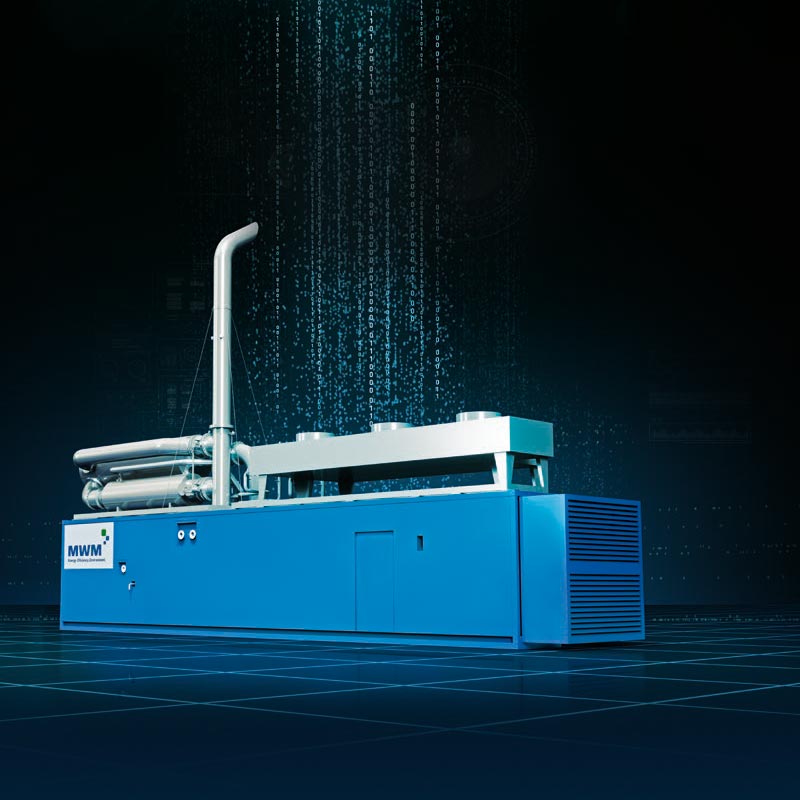

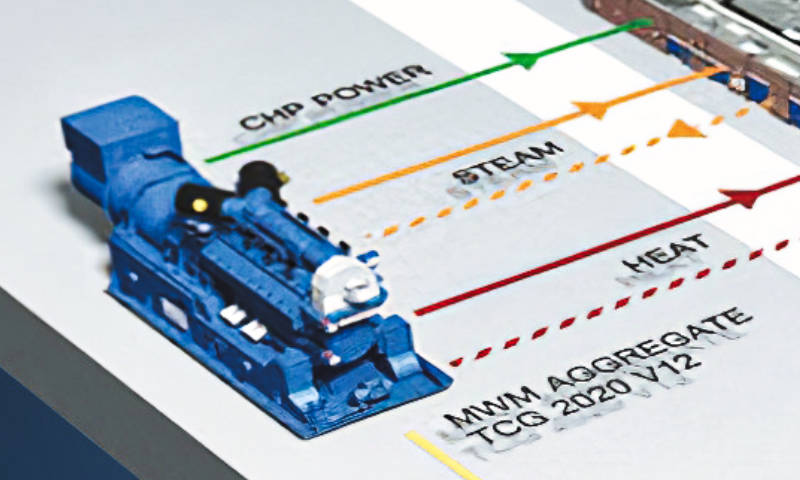

MWM gas engines and container cogeneration power plants provide customers with an optimum solution for distributed energy generation. Due to their high performance, efficiency, and flexibility, they are deployed for heat and power generation in numerous industries. MWM gas engines and generator sets cover an electrical output range from 400 to 4,500 kW. With these units, it is possible to implement power plants with an output of 100,000 kW or more. With genuine MWM spare parts, you can protect both the performance and the original state of your engine—for long-term secure, effective operation of your plant.

MWM Engines and Cogeneration Power Plants Around the Globe

MWM gas engines and container cogeneration power plants are deployed around the globe in numerous industries for energy generation. MWM customers benefit from the company’s more than 150 years of experience. From a single source, they can get integrated systems in the form of container cogeneration power plants and CHP plants. Over the past 15 years, MWM has delivered gas engines and generator sets with a total output of more than 10.2 GW around the globe.

Flexible Use of Various Gas Types

MWM engines impress customers around the globe with their cutting-edge electrical and thermal efficiency. The generator sets can be operated with various gas types, including natural gas, APG, propane gas, biogas, shale gas, mine gas, landfill gas, sewage gas, syngas, and hydrogen admixtures. Thanks to their low operating and service costs and high availability, the gas engines achieve efficiency levels of more than 90 percent.

More Than 150 Years of Experience

The design of the MWM engines is based on the expertise gained in more than 150 years and a strong innovative drive and is subject to ongoing technical development and adaptation to current market requirements. Benefit from state-of-the-art solutions customized to your heat and power generation needs in the form of MWM gas engines, container cogeneration power plants, and genuine spare parts.

Overview: MWM Gas Engines

MWM Energy Projects in Central Asia and

Eastern Europe

Here you can find a selection of successfully implemented projects with MWM gas engines and CHP plants.

MWM Gas Engines, Container Cogeneration Power Plants, and Spare Parts: Benefits at a Glance

MWM Engines and Energy Solutions Around the Globe

- Generator sets, container cogeneration power plants, and CHP plants for various industries and fields of application

- Integrated systems for energy generation from one source

- More than 4,900 MWM power generator sets around the globe

More Than 150 Years of Experience in the Development of Energy Solutions

- High technical expertise in the development and manufacturing of gas engines

- Continuous technical development and customization of MWM generator sets and cogeneration power plants

- Energy solutions for distributed heat and power generation, custom-tailored to your needs

Maximum Efficiency, Maximum Flexibility

- MWM engines are suitable for a wide range of gas types, including natural gas, APG, propane gas, biogas, shale gas, mine gas, landfill gas, sewage gas, syngas, and hydrogen admixtures.

- Overall efficiency of up to 90 percent

- Low service and operating costs

MWM Engines and Container Cogeneration Power Plants in Action

Your Sales and Service Inquiries

Competence for Your Energy Future

MWM provides you with expert advice and reliable service for your planning, purchase, or maintenance. Our dedicated team will assist you with their expertise and full commitment to ensure that your projects run smoothly. Benefit from custom-tailored solutions for a reliable pathway to your goal.