MWM TCG 2020 Gas Engine

Optimum Energy Efficiency for Your Plant Operation

Versatile Solution for Various Requirements

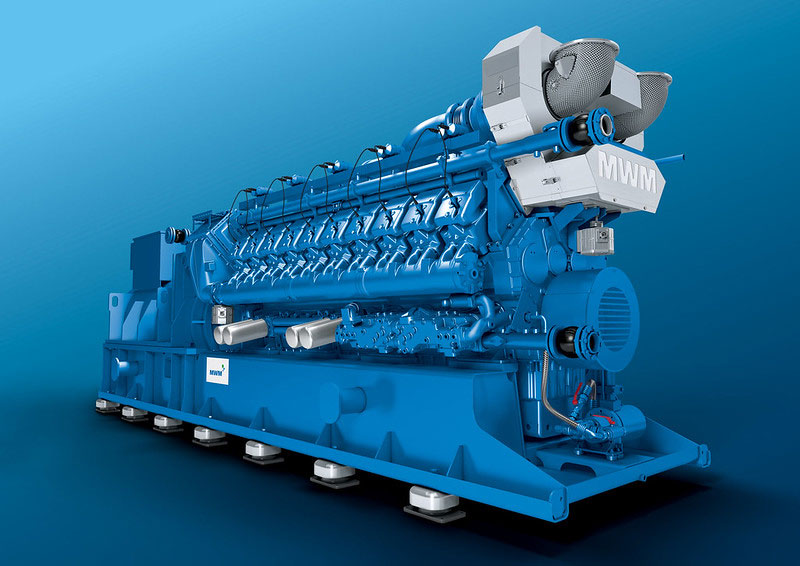

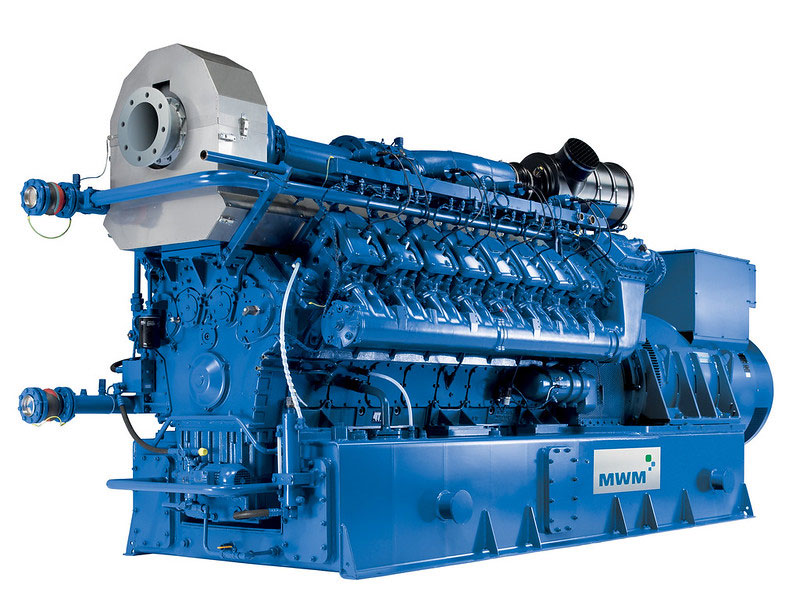

The MWM TCG 2020 gas engine is used in numerous industries worldwide, e.g. in industrial production, in municipal energy supply, and in projects of independent energy suppliers. The series is particularly well-suited for medium- and large-scale cogeneration projects, with an electrical output range from 1,000 to 1,560 kW and higher. The engine efficiently generates thermal energy that can be used for heating, hot water supply, or industrial processes, without energy losses. In addition to natural gas, it is also possible to make efficient use of biogas, landfill gas, sewage gas, mine gas, and other gases.

High Efficiency, Low Operating Costs

The various versions of the TCG 2020, including the specially optimized V12 version for natural gas (RW) and the version for biogas (XW), are characterized by very low operating costs and high efficiency. They offer long maintenance intervals, low lubricating oil consumption, and a user-friendly design. Additionally, there are special models such as the TCG 2020 K, which is tailored to special ambient conditions, e.g. for use at high altitudes or with high intake air temperatures.

Proven Technology in Use Worldwide

The more than 2,000 generator sets of the TCG 2020 series delivered worldwide furnish evidence of the system’s feasibility. These engines generate a combined electrical output of about 2.8 million kW. They are used in a wide range of applications, including the waste-to-energy sector, greenhouse energy supply, and healthcare facilities.

MWM TCG 2020 Gas Engine—Benefits at a Glance

Wide Range of Deployment Options

- Ideal for energy generation in recycling plants, district heating networks, healthcare, greenhouses, and industrial projects

- Proven in IPP and municipal utilities applications

- Adaptable to the technical requirements of various industries

- Can be used efficiently in modern concepts for distributed heat and power generation

High Reliability in Continuous Operation

- Long maintenance intervals for operation with fewer interruptions

- Designed for continuous use under demanding conditions

- Sturdy design and high operational reliability for a longer service life

- Reliable partner for plants with high availability requirements

Low Operating Costs

- Up to 50% less lubricating oil consumption than comparable systems

- Longer maintenance cycles increase uptime, reduced service costs

- Particularly economical in natural gas operation with optimized efficiency of up to 43% (under ISO conditions)

Optimum Performance in Island-Mode Operation

Why the TCG 2020K Is Especially Suitable for Off-Grid Applications

- Developed especially for off-grid operation, ideal for protection against power failures or for deployment in closed energy systems

- Adapted to high intake air temperatures and high altitudes, therefore suitable for demanding climate conditions

- Optimized combustion thanks to reduced crevice volume reduces gas consumption and emissions

- Saves up to 15% gas per year, reducing operating costs

- Extended maintenance intervals thanks to clean intake air and efficient blow-by recirculation

- High efficiency through improved turbocharger design and water-cooled bearing housings

Overview: Deployment Options of the TCG 2020

FAQ

Why is the MWM TCG 2020 a good choice for operators?

The TCG 2020 stands out with its high electrical and thermal efficiency, low operating costs, and compact design. Moreover, it is compatible with various types of gas.

Which fields of application is the MWM TCG 2020 especially suitable for?

The gas engine is suitable for a wide range of applications, including recycling plants, heating networks, hospitals, greenhouses, industry, and IPP projects.

What are the benefits of the series in terms of operating costs?

Thanks to the compact plant design, the TCG 2020 series achieves a high power density with a very small footprint. This not only facilitates the planning and implementation of projects in confined spaces, but also transportation and installation.

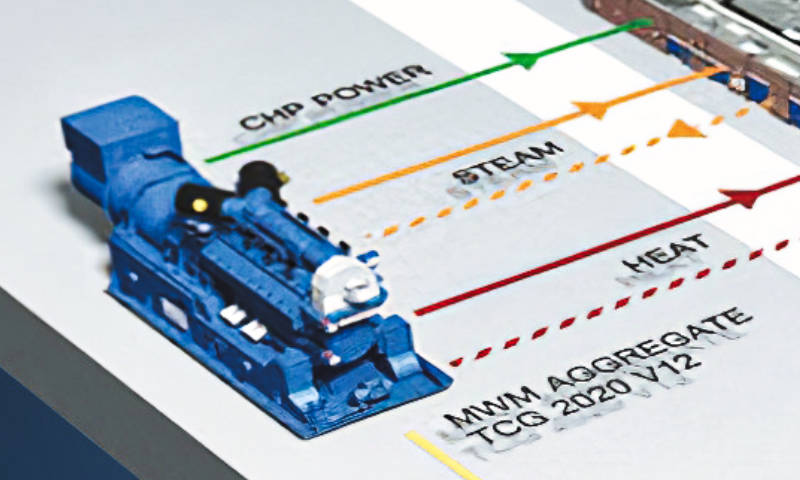

What are the benefits of using the MWM TCG 2020 in CHP plants?

The simultaneous generation of heat and power boosts the overall efficiency of the engine. At the same time, it cuts operating costs and helps to reduce emissions.

What electrical output range does the MWM TCG 2020 cover?

The TCG 2020 is available in the output range from 1,000 to 1,560 kW. Therefore, it is the ideal choice for energy projects that necessitate a compact, high-performance solution.

How does the TCG 2020 behave under demanding ambient conditions?

The series also features variants such as the TCG 2020 K, which was developed especially for deployment under non-standard conditions, such as high altitudes or high ambient temperatures. Thus, high performance is possible even under difficult operating conditions.

Technical Information on the TCG 2020 for Download

MWM TCG 2020 Gas Engine

NOTICE: Click this brochure to access the digital publishing platform issuu.com. This website is governed by the issuu Privacy Policy.

All languages on issuu:

Download PDF:

Insights: Application of the MWM TCG 2020

Visit the international MWM website for information on reference projects in which the TCG 2020 is being used successfully in various applications and industries worldwide.

Your Sales and Service Inquiries

Competence for Your Energy Future

MWM provides you with expert advice and reliable service for your planning, purchase, or maintenance. Our dedicated team will assist you with their expertise and full commitment to ensure that your projects run smoothly. Benefit from custom-tailored solutions for a reliable pathway to your goal.

Your Personal MWM Contact

Make an Appointment with Your Personal MWM Contact

Performance Data: TCG 2020 Gas Engine

Natural Gas Applications, NOx ≤ 500 mg/Nm3 *

| TCG 2020 V12 RW = Optimized for high total efficiency at requested power |

||

|---|---|---|

| Engine type | 50 Hz | |

| Electrical output | kW | 1,000 |

| Thermal output ± 8% | kW | 1,056 |

| Electrical efficiency | % | 43.0 |

| Thermal efficiency | % | 45.4 |

| Total efficiency | % | 88.4 |

| Power to heat ratio ** | 0.95 | |

| TCG 2020 V12 K K = Optimized for robustness and low CAPEX |

|||

|---|---|---|---|

| Engine type | 50 Hz | 60 Hz | |

| Electrical output | kW | 1,125 | 1,125 |

| Thermal output ± 8% | kW | 1,251 | 1,262 |

| Electrical efficiency | % | 41.0 | 40.7 |

| Thermal efficiency | % | 45.6 | 45.6 |

| Total efficiency | % | 86.6 | 86.3 |

| Power to heat ratio ** | 0.90 | 0.89 | |

| TCG 2020 V12 R = Optimized for high total efficiency |

|||

|---|---|---|---|

| Engine type | 50 Hz | 60 Hz | |

| Electrical output | kW | 1200 | 1200 |

| Thermal output ± 8% | kW | 1,189 | 1196 |

| Electrical efficiency | % | 43.7 | 43.4 |

| Thermal efficiency | % | 43.3 | 43.2 |

| Total efficiency | % | 87.0 | 86.6 |

| Power to heat ratio ** | 1.00 | 1.00 | |

| TCG 2020 V16 K K = Optimized for robustness and low CAPEX |

|||

|---|---|---|---|

| Engine type | 50 Hz | 60 Hz | |

| Electrical output | kW | 1,500 | 1,500 |

| Thermal output ± 8% | kW | 1,675 | 1,686 |

| Electrical efficiency | % | 40.9 | 40.6 |

| Thermal efficiency | % | 45.7 | 45.7 |

| Total efficiency | % | 86.6 | 86.3 |

| Power to heat ratio ** | 0.89 | 0.89 | |

| TCG 2020 V16 R = Optimized for high total efficiency |

|||

|---|---|---|---|

| Engine type | 50 Hz | 60 Hz | |

| Electrical output | kW | 1,560 | 1,560 |

| Thermal output ± 8% | kW | 1,576 | 1,589 |

| Electrical efficiency | % | 43.3 | 43.0 |

| Thermal efficiency | % | 43.8 | 43.8 |

| Total efficiency | % | 87.1 | 86.8 |

| Power to heat ratio ** | 0.99 | 0.98 | |

* “after commissioning (E10)”

The data in this chart are for information only and are not binding. The information given in the offer is authoritative. Further generator set variants are available with different generators.

Biogas, Landfill Gas, and Sewage Gas Applications, NOx ≤ 500 mg/Nm3 *

| TCG 2020 V12 XW = Optimized for operation with biogases at requested power |

||

|---|---|---|

| Engine type | 50 Hz | |

| Electrical output | kW | 1,000 |

| Thermal output ± 8% | kW | 1,035 |

| Electrical efficiency | % | 42.6 |

| Thermal efficiency | % | 44.1 |

| Total efficiency | % | 86.7 |

| Power to heat ratio ** | 0.97 | |

| TCG 2020 V12 X = Optimized for operation with biogases |

|||

|---|---|---|---|

| Engine type | 50 Hz | 60 Hz | |

| Electrical output | kW | 1,200 | 1,200 |

| Thermal output ± 8% | kW | 1,192 | 1,201 |

| Electrical efficiency | % | 43.0 | 42.7 |

| Thermal efficiency | % | 42.7 | 42.7 |

| Total efficiency | % | 85.7 | 85.4 |

| Power to heat ratio ** | 1.00 | 1.00 | |

| TCG 2020 V16 X = Optimized for operation with biogases |

|||

|---|---|---|---|

| Engine type | 50 Hz | 60 Hz | |

| Electrical output | kW | 1,560 | 1,560 |

| Thermal output ± 8% | kW | 1,566 | 1,580 |

| Electrical efficiency | % | 42.7 | 42.3 |

| Thermal efficiency | % | 42.9 | 42.8 |

| Total efficiency | % | 85.6 | 85.1 |

| Power to heat ratio ** | 1.00 | 0.99 | |

* 5% O2 and dry exhaust gases

** The power to heat ratio is calculated by dividing the electrical efficiency by the thermal efficiency. Please remember that this is a theoretical value that may deviate from actually measured values.

The data in this chart are for information only and are not binding. The information given in the offer is authoritative. Further generator set variants are available with different generators.

Protect Your Investment

For a Strong Future for Your Engines

Genuine MWM spare parts suit your plant perfectly, guaranteeing performance, efficiency, and a long useful life. Always get the best quality for your energy supply.

Specifications and Service Intervals: TCG 2020 Gas Engine

Dimensions and Weights

| TCG 2020 V12 RW = Optimized for high total efficiency at requested power XW = Optimized for operation with biogases at requested power |

||

|---|---|---|

| Engine type | 50 Hz | |

| Length | mm | 4,660 |

| Width | mm | 1,810 |

| Height | mm | 2,210 |

| Dry weight genset | kg | 11,200 |

| Bore / stroke | mm | 170/195 |

| Displacement | dm3 | 53.1 |

| Speed | min-1 | 1,500 |

| Mean piston speed | m/s | 9.8 |

| TCG 2020 V12 K K = Optimized for robustness and low CAPEX |

|||

|---|---|---|---|

| Engine type | 50 Hz | 60 Hz | |

| Length | mm | 4,790 | 5,970 |

| Width | mm | 1,810 | 1,790 |

| Height | mm | 2,210 | 2,210 |

| Dry weight genset | kg | 11,700 | 13,000 |

| Bore / stroke | mm | 170/195 | 170/195 |

| Displacement | dm3 | 53.1 | 53.1 |

| Speed | min-1 | 1,500 | 1,500 |

| Mean piston speed | m/s | 9.8 | 9.8 |

| TCG 2020 V12 R = Optimized for high total efficiency X = Optimized for operation with biogases |

|||

|---|---|---|---|

| Engine type | 50 Hz | 60 Hz | |

| Length | mm | 4,790 | 5,970 |

| Width | mm | 1,810 | 1,790 |

| Height | mm | 2,210 | 2,210 |

| Dry weight genset | kg | 11,700 | 13,000 |

| Bore / stroke | mm | 170/195 | 170/195 |

| Displacement | dm3 | 53.1 | 53.1 |

| Speed | min-1 | 1,500 | 1,500 |

| Mean piston speed | m/s | 9.8 | 9.8 |

| TCG 2020 V16 K K = Optimized for robustness and low CAPEX |

|||

|---|---|---|---|

| Engine type | 50 Hz | 60 Hz | |

| Length | mm | 5,430 | 6,640 |

| Width | mm | 1,810 | 1,790 |

| Height | mm | 2,210 | 2,210 |

| Dry weight genset | kg | 13,300 | 14,900 |

| Bore / stroke | mm | 170/195 | 170/195 |

| Displacement | dm3 | 70.8 | 70.8 |

| Speed | min-1 | 1,500 | 1,500 |

| Mean piston speed | m/s | 9.8 | 9.8 |

| TCG 2020 V16 R = Optimized for high total efficiency X = Optimized for operation with biogases |

|||

|---|---|---|---|

| Engine type | 50 Hz | 60 Hz | |

| Length | mm | 5,430 | 6,640 |

| Width | mm | 1,810 | 1,790 |

| Height | mm | 2,210 | 2,210 |

| Dry weight genset | kg | 13,300 | 14,900 |

| Bore / stroke | mm | 170/195 | 170/195 |

| Displacement | dm3 | 70.8 | 70.8 |

| Speed | min-1 | 1,500 | 1,500 |

| Mean piston speed | m/s | 9.8 | 9.8 |

* On request

The data in this chart are for information only and are not binding. The information given in the offer is authoritative. Further generator set variants are available with different generators.

Service Intervals

| TCG 2020 V12, V16, V12 K, V16 | First service (check valve clearance) | Cylinder head inspection | Major overhaul |

|---|---|---|---|

| Natural gas, purified biogas, sewage gas, and landfill gas | 4,000 oh | 32,000 oh* | 64,000 oh |

| Unpurified biogas, sewage gas, and landfill gas | 2,000 oh | 16,000 oh* | 64,000 oh |

| TCG 2020 V12 RW = Optimized for high total efficiency at requested power XW = Optimized for operation with biogases at requested power |

First service (check valve clearance) | Cylinder head inspection | Major overhaul |

|---|---|---|---|

| Natural gas | 4,000 oh | 40,000 oh* | 80,000 oh |

| Purified biogas, sewage gas, and landfill gas | 4,000 oh | 32,000 oh* | 64,000 oh |

| Unpurified biogas, sewage gas, and landfill gas | 2,000 oh | 16,000 oh* | 64,000 oh |

* “after commissioning (E10)”

The data in this chart are for information only and are not binding. The information given in the offer is authoritative. Further generator set variants are available with different generators.